A Unique One-Off Project: Custom 3D Printed Light Covers

- Derrin

- Jan 14

- 2 min read

At Carelli LLC, no project is too unconventional for our team. We pride ourselves on our ability to provide innovative solutions tailored to the unique needs of our clients. Recently, we had the opportunity to tackle a fun and challenging one-off project that perfectly exemplifies this approach.

A client came to us with a problem that seemed almost impossible to solve: their light covers had broken, and replacements were nowhere to be found. The manufacturer had discontinued the product, and after an exhaustive search online, it was clear that standard options simply weren’t available. That’s when Carelli LLC stepped in to find a custom solution.

The Challenge:

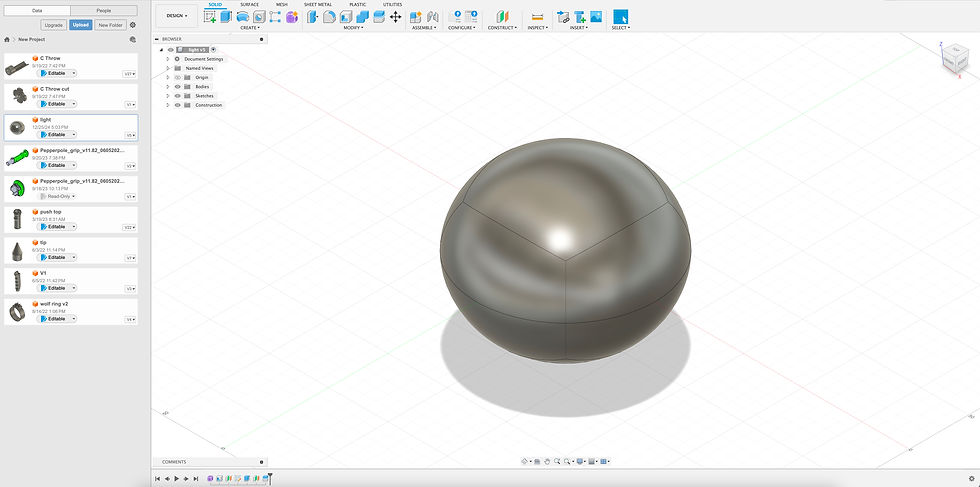

The broken light cover presented a unique challenge. With no original replacement available, I decided to take matters into my own hands. Using the fragments of the broken cover as a guide, I meticulously modeled the design in the 3D CAD program Fusion 360. This step required careful measurement and attention to detail to ensure the new covers would fit seamlessly into the existing fixtures.

Bringing the Idea to Life:

Once the design was finalized, it was time to bring the light covers to life. Using a high-quality 3D printer, I carefully printed the covers layer by layer. The process required patience and attention to detail to ensure the final product met both functional and aesthetic standards.

Perfecting the Surface:

After printing, I noticed the surface of the covers had a slightly textured finish due to the 3D printing process. To make the surface more like the original light covers, I used a fine-grit sanding tool to carefully smooth out the exterior. This step not only improved the appearance but also ensured the light diffused evenly, just as it had with the original covers. Sanding required a steady hand and an eye for detail, but the results were well worth the effort.

Adding the Finishing Touch:

While the sanding process improved the texture, the 3D printed covers still had a matte finish, unlike the glossy finish of the originals. To achieve the desired glossy look, I applied a clear coat of polycrylic. This not only replicated the original aesthetic but also added an extra layer of protection to the covers. The final result was a seamless match that restored the fixtures to their original appearance.

The Final Results:

The transformation was incredible. On the left, you can see the broken light cover that originally presented the challenge. On the right is the replacement we created—a glossy, perfectly fitted replica that restored the light fixture to its original functionality and beauty. This comparison showcases the dedication and craftsmanship that went into every step of the process.

Why We Do What We Do

This project highlights what Carelli LLC is all about: innovative craftsmanship and a commitment to exceeding our clients’ expectations. Whether it’s a large-scale construction project or a small, specialized task like this one, we approach every challenge with the same level of care and ingenuity.

Have a unique problem that requires a custom solution? Reach out to us at Carelli LLC. We’re here to make your vision a reality.

Comments